Robots just jumped from lab demos to real jobs—on factory lines, in ORs, farms, and even your doorstep. For years, you’ve seen glossy videos. Cool. But you need to know what’s real, what works, and what you can act on now. The future of robotics isn’t a far-off dream. It’s AI in robotics delivering value in hospitals, warehouses, fields, and retail. And yes, humanoid robots 2025 are starting to matter.

The hard part? Sorting real progress from demo-ware. This guide cuts the noise. You’ll see ten examples with proof you can check yourself—press releases, product pages, and videos—plus simple next steps if you want to pilot or buy. Each section explains what the tech does today, why 2025 is the moment, and how to scope a small, low-risk trial inside your org.

You’ll get numbers, links, and short playbooks. No fluff. No hype. When something’s early, I’ll tell you. When it’s deployable, I’ll show you how. By the end, you’ll know where humanoids fit, which surgical platforms just got cleared, how drones hit real-world SLAs, why weed-zapping lasers can pay off, and how 3D printers are building houses on Earth—while NASA funds the path to the Moon. Let’s get practical.

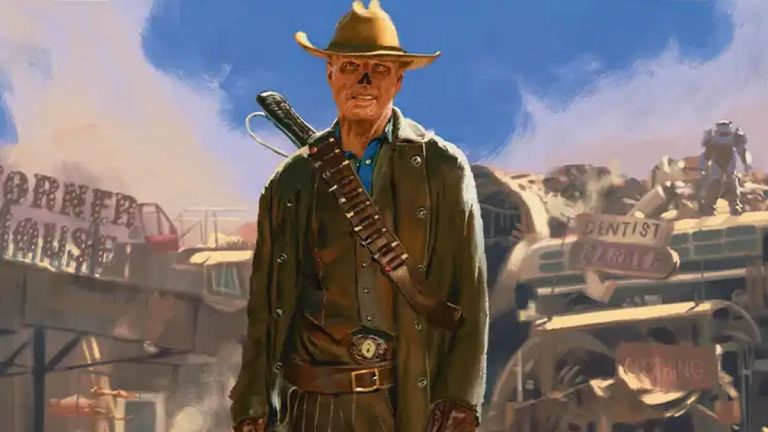

1. Figure’s Humanoids Move From Pilots to Real Work (humanoid robots 2025)

Figure builds general-purpose humanoids for factory work now, with a roadmap that points to the home. 2025 matters because the company shifted from short trials to daily, in-plant testing and data collection with BMW. BMW confirms Figure 02 robots were “tested successfully … in a real production environment” at Plant Spartanburg, with teams now working through results to support future applications. That signals progress, not a marketing video.

Funding is real: $675M Series B (Feb 29, 2024) with a collaboration agreement with OpenAI—backed by Microsoft, NVIDIA, Jeff Bezos, and others. That’s fuel for faster productization and AI training.

In 2025, TIME profiled Figure’s push toward a household-capable “Figure 03,” while noting candid limits and the reliance on long shifts of data capture and human-guided training. It’s honest about what works today and what’s still hard.

What you can do now: if you’re a manufacturer, run a POC scoping exercise: define 1–2 ergonomic or low-variance tasks (fixture loading, tote movement), set a data capture plan (hours, scenarios), and align on success metrics (cycle time window, safety events, uptime). This keeps you ready for humanoid robots 2025 pilots without overspending on hardware. Keywords: humanoid robots 2025; general-purpose robots; AI in robotics.

2. Tesla Optimus: Viral Demos, Steady Capability Gains

What improved: Tesla’s Optimus Gen-2 is ~10 kg lighter with ~30% faster walking and more dexterous hands than Gen-1, shown in Dec 2023 updates and widely covered by tech outlets. These are material steps toward useful manipulation.

What’s new in 2025: fresh social clips show Optimus practicing martial arts/balance. Treat these as promising but unproven until third-party verification confirms autonomy vs. teleop. Use public demos as a “watch list,” not a purchase trigger.

Independent context: trackers and reviewers continue to question how much is autonomous vs. teleoperated in many humanoid demos (not just Tesla). Pair company posts with independent reporting before you set expectations.

Actionable takeaway: set an internal review gate for late 2025–2026. Build an evaluation brief: target tasks, success metrics (grasp success %, mean time between fails), safety constraints, and integration points (fleet mgmt, guarding). Keep conversations warm, but don’t plan a factory swap yet.

3. Boston Dynamics’ New Electric Atlas Is Built for Work

Boston Dynamics retired the hydraulic Atlas and introduced a fully electric Atlas “designed for real-world applications.” That matters for reliability, maintenance, and cleanliness around factory assets.

The company shows Atlas handling real parts (e.g., engine covers) and positioning itself as an R&D-to-production bridge for advanced manufacturing, with Hyundai as an early partner environment. Electric actuators and a cleaner design reduce leak and service risks versus hydraulics.

What you can do now: if you’re in automotive or heavy assembly, prepare pilot cells for mobile manipulation—safe zones, fixtures, part trays, and test scripts (pick-place sequences, misalignment cases). Define service SLAs and a failure-reporting loop. Keywords: future of robotics; electric humanoid; industrial robots.

4. Agility’s Digit + RoboFab: Humanoids at Production Scale

Agility opened RoboFab in Salem, Oregon with capacity to scale to 10,000 robots/year at maturity (hundreds in early years). The Agility Partner Program (APP) received first Digit deliveries in 2024, with general availability in 2025—a real production ramp, not a one-off demo.

Digit focuses on warehouse tote work: moving, loading, unloading, and recycling totes—boring work, perfect for steady ROI when reliability is high. Local 2025 coverage highlights how the plant and hiring support scale.

What you can do now: if you run DCs/3PLs, pick a single tote flow (e.g., induction → staging) and map cycle time, failure modes (dropped totes), and handoffs with conveyors or AMRs. Pilot 1–2 Digit units in a fenced or supervised cell.

5. NVIDIA’s GR00T + Jetson Thor: The ‘Brain’ for Humanoids

NVIDIA announced Project GR00T—foundation models for embodied AI—and a major Isaac platform update, plus Jetson Thor edge computers for humanoids. In short: faster skill learning, better sim-to-real, and compute built for whole-body control.

Jetson Thor brings up to ~2070 FP4 TFLOPS and up to 128 GB memory in 40–130 W envelopes—headroom for vision-language models, planning, and high-rate sensing. Specs are public and targeted squarely at “supercomputers for humanoids.”

In 2025, NVIDIA released Isaac GR00T N1/N1.5 updates and developer posts tying synthetic data generation (“GR00T-Dreams”) to skill learning, showing how buyers can expect faster capability updates from partners building on Isaac.

What you can do now: when you evaluate a humanoid, ask: Which Isaac/GR00T release? Which Thor module? What sim assets and datasets ship with the robot? This will tell you how quickly new skills can arrive and what on-prem compute you’ll need. Keywords: AI in robotics; robot foundation models; Isaac.

6. Surgery Gets a Major Upgrade: Intuitive’s da Vinci 5

The da Vinci 5 earned FDA 510(k) clearance (Mar 14, 2024). It adds ~10,000× more compute and a new Force Feedback capability that, in testing, let surgeons apply up to 43% less force on tissue during simulated tasks—important for gentler handling.

Intuitive’s platform page details 150+ design innovations, better 3D vision, and workflow tweaks aimed at throughput. If you run surgical service lines, this is less “cool robot,” more OR productivity plus training data for skills improvement.

What you can do now: hospitals should scope service-line pilots (urology, GYN, general), align on case mix, console time, complications, and turnover times, and set up surgeon training with Force Feedback instruments. Confirm procurement timing and capital plan. Keywords: surgical robots; AI in robotics; operating room automation.

7. New Surgical Challenger: J&J OTTAVA’s First U.S. Cases (2025)

J&J’s OTTAVA received IDE approval in late 2024, enabling U.S. clinical trials. On Apr 14, 2025, J&J reported first U.S. clinical cases completed, signaling real competitive pressure in multi-port surgical robotics and new room configurations to consider. JNJ.com+1

Early trade coverage confirms those initial cases. For hospitals, this means more choice and leverage—especially if room layout, arm geometry, or training integration better fits your workflows than incumbents. fiercebiotech.com

What you can do now: form a small technology assessment group (surgeons + nursing + biomed), request site visits where trials occur, and build a side-by-side matrix (instrument set, maintenance, footprint, data/tele-mentoring).

8. Drone Delivery at Retail Scale: Walmart + Partners

Walmart passed 150,000+ drone deliveries since 2021 and announced 2025 expansions to new states and cities through partners like Wing and Zipline. This isn’t a lab. It’s a retailer using drones at real volumes and publishing milestones.

In 2025, Wing and Walmart detailed expansions across multiple states. Coverage lays out markets, service areas, and what a typical SKU/weight/SLA looks like for suburban customers.

What you can do now: if you’re a retailer or city, start with airspace and ops partners. Pick two zip codes, define service radius, weight limits, and 15–30 min delivery windows. Use partner fleets first; don’t build your own. Keywords: last-mile drones; retail logistics; AI in robotics.

9. AI Farming That Vaporizes Weeds: Carbon Robotics LaserWeeder

Carbon Robotics’ LaserWeeder uses AI vision plus high-power lasers to kill weeds without herbicides. Case studies report lower costs and strong weed-kill counts at commercial scale—Western Growers cites “10 billion weeds killed” across farms.

Hardware matters: the latest machines tout up to ~600,000 weeds/hour with 24 lasers and 24 NVIDIA GPUs—serious throughput for specialty crops. Farmers report labor savings and yield protection because you’re not spraying crops.

What you can do now: budget either capex or service models (ask your dealer), train crews on safety perimeters, and pilot on a single block with a before/after herbicide spend and weed-pressure log. Keywords: agriculture robots; AI in robotics; precision weeding.

10. Robots Are Printing Buildings: ICON & COBOD (Earth and Moon)

ICON × NASA are funding paths to lunar construction (Project Olympus). NASA’s 2025 update continues to back testing for off-world building with regolith-based materials and large-scale printers. That research also feeds back into Earth projects. NASA

Coverage in 2025 shows ICON’s ongoing tests and mission plans, while COBOD advances multi-functional construction printers/robots delivering large projects. New Atlas reports a national program in Qatar to 3D-print hundreds of schools, highlighting how this scales beyond tiny demo sheds. 3dprint.com+2COBOD+2

What you can do now: developers and agencies can start with permitting consultations, pick simple use-cases (utility buildings, single-story housing), and pre-qualify mix suppliers. Create a cost model with crew size, print hours, cure time, and finishing trades. Keywords: construction robots; 3D-printed buildings; future of robotics.