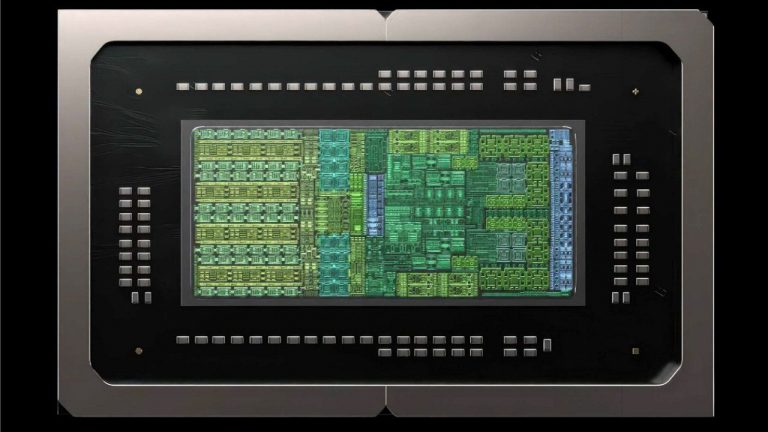

Intel held its inaugural Intel Foundry Services Direct Connect event today. It essentially marks the launch of Intel’s new manufacturing strategy, bringing all of its customer manufacturing, system design, packaging and connectivity solutions under one umbrella.

During the event, Intel outlined its new process roadmap which included the announcement of its 14A node. It’s estimated to hit the market in 2026 or 2027 and marks the first node to make use of High-NA lithography. It’s expected to incorporate PowerVia backside power delivery and RibbonFET GAA transistors. Suffice to say, this stuff is bleeding edge.

Intel didn’t provide information on what products will be built on the new node, but it’s safe to say enterprise tier products will be a priority, though consumer laptop and desktop chips are sure to benefit from it too.

The announcement of the 14A node follows what has become known as Intel’s ‘four nodes in five years’ roadmap, which is now all but completed. It began with the launch of Intel 7, which is the node used to make 12th, 13th and 14th Gen processors. Parts of Meteor Lake are built using the Intel 4 node. Intel 3 is less relevant to consumers as it is used for Sierra Forest and Granite Rapids Xeon families.

20A is where it gets interesting for consumers as its the node Intel will use to build its Arrow Lake CPU family, which is expected to arrive later in the year and replace the current 14th Gen desktop lineup. Beyond 20A lies 18A, which is set to start production later in 2024. Intel’s next-next Gen Panther Lake CPU family is expected to use this node.

(Image credit: Intel)

This aggressive strategy was seen as very risky, especially given the well-publicized issues and delays Intel had with its 14nm and 10nm nodes. So, the fact that Intel has pretty much pulled it off is very impressive. Intel remains confident that it can take back the process leadership crown from TSMC with its 18A node.

The Direct Connect event isn’t all about Intel’s own chips. Far from it. It’s about opening up its manufacturing facilities to external partners. Intel says it hopes to become the world’s second largest foundry—behind only TSMC— by 2030.

It’s on the right path too, scoring Microsoft as a customer for chips built on its 18A node. Microsoft CEO Satya Nadella said: “We are in the midst of a very exciting platform shift that will fundamentally transform productivity for every individual organization and the entire industry”.

Hmm, what could that mean? My assumption is it’s a custom AI chip. Intel says that once everything is factored in, the deal could be worth as much as $15 billion over its lifetime.

(Image credit: Intel)

Microsoft isn’t Intel’s only design and manufacturing win. Other partner companies include Ericsson, Cadence, Keysight, Lorentz, and Siemens. Intel also announced a collaboration with Arm, describing it as an “Emerging Business Initiative”. That’s a development that holds a lot of potential. Intel is surely having discussions with the likes of Qualcomm and Broadcom, but just imagine if it could land Nvidia or Apple as customers? That would represent a seismic shift in the semiconductor industry.

Intel has its work cut out to beat AMD in the server CPU space, and it’s not managed to ride the AI wave anywhere near as much as it would have liked, but with its aggressive roadmap and foundry strategy, it’s laying the foundation for a big second half of the decade.